1

/

of

4

Domenic Bathroom

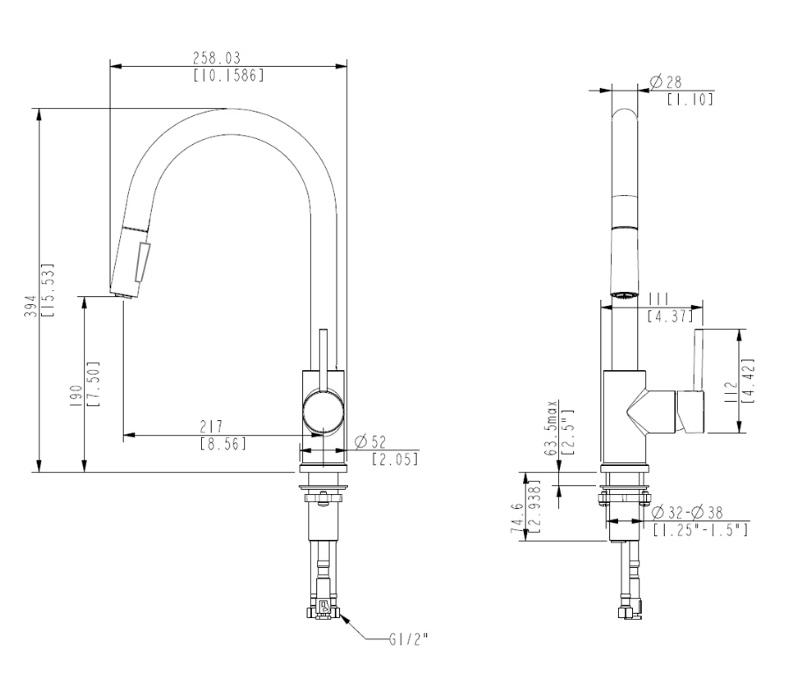

ELEMENTI UNO GOOSE NECK KITCHEN MIXER C/W POS PULL-OUT

ELEMENTI UNO GOOSE NECK KITCHEN MIXER C/W POS PULL-OUT

Regular price

$559.00

Regular price

$1,315.00

Sale price

$559.00

Unit price

/

per

Couldn't load pickup availability

The Uno collection offers a glamorous look without being too ostentatious. After years of chrome dominating as the must-have metal, there has been a move away from the high shine, perfect finish of Chrome towards finishes like Brushed Nickel, Gun Metal, Black and Brushed Brass.

For More Information, Please Find Elementi Uno Gooseneck Kitchen Mixer | Robertson Bathware

Guarantee5 Year Guarantee on coloured finish

Guarantee10 Year Guarantee

4 Star WELS ratingMore than 6.0 but not more than 7.5 litres per minute.

Mains PressureSuitable for Mains Pressure.

Flawless FinishAdvanced plating provides a durable surface with a long lasting finish

Effortless ControlAdvanced cartridge technology provides a wide operating angle and smooth operation

Smooth FlowAerator reduces scaling while delivering a smooth even flow

IndicatorsIncludes standard and coloured indicators.

Forward rotating handleForward rotating handle prevents the lever hitting the splashback.

Pull Out SprayMake life easier with a pull out spray.

Swivel SpoutThe Swivel spout provides space, flexibility and ease of use.

Chrome PlateA base of copper is first applied followed by a layer of nickel and then finally a hard gloss coating of chromium to achieve a shiny hard wearing finish.

Electroplated: Gun MetalElectrical current is used to dissolve components into Lacquer that then adhere to the surface.

Electroplated: BlackElectrical current is used to dissolve components into Lacquer that then adhere to the surface.

Electroplated with PVD: Brushed NickelElectrical current is used to dissolve components into Lacquer that then adhere to the surface. A thin metal-spray coating in the form of very thin layers is finally applied using PVD process.

Electroplated with PVD: Brushed BrassElectrical current is used to dissolve components into Lacquer that then adhere to the surface. A thin metal-spray coating in the form of very thin layers is finally applied using PVD process.

Share